The following is a transcript of an investigative report on Full Measure News. Click on the link at the end of the transcript to watch the video story.

Today we begin with a bit of a mystery. Why, more than a year into the Covid-19 pandemic, are some products still hard or impossible to find at the grocery store– Even those seemingly unrelated to pandemic necessities? Lisa Fletcher looked into the question and found it has a lot to do with America’s surprisingly fragile supply chain.

Christine Gutleben Becker is a businesswoman and mom of three in Washington D.C.’s northern suburbs. After making the weekly run to the grocery store, she’s become too used to the new reality for consumers everywhere.

Christine Gutleben Becker: In some ways shopping feels like an experiment. What are we going to get? What can we make with what we’re going to get? And it feels par for the course. I think in these times almost normal.

The new ‘normal’ means missing items, sometimes empty shelves.

Lisa: Have you noticed that your choices have diminished in terms of the same type of product with different brands or multiple types of product within a brand?

Gutleben Becker: Yes, absolutely. So today I couldn’t get my favorite tortilla brand and I actually realized that I haven’t been able to get it, I think, for the past year. And so, we’ve learned to just accept other, other types of tortillas and it feels like a small price to pay.

Tortilla’s are just one of the many products that have seen dramatic sales increases thanks to Covid.

In the first six months of the pandemic, the products that saw the biggest jump in sales were hand sanitizer – up 838%; soaps – up 65%; and disinfectants – up 61%.

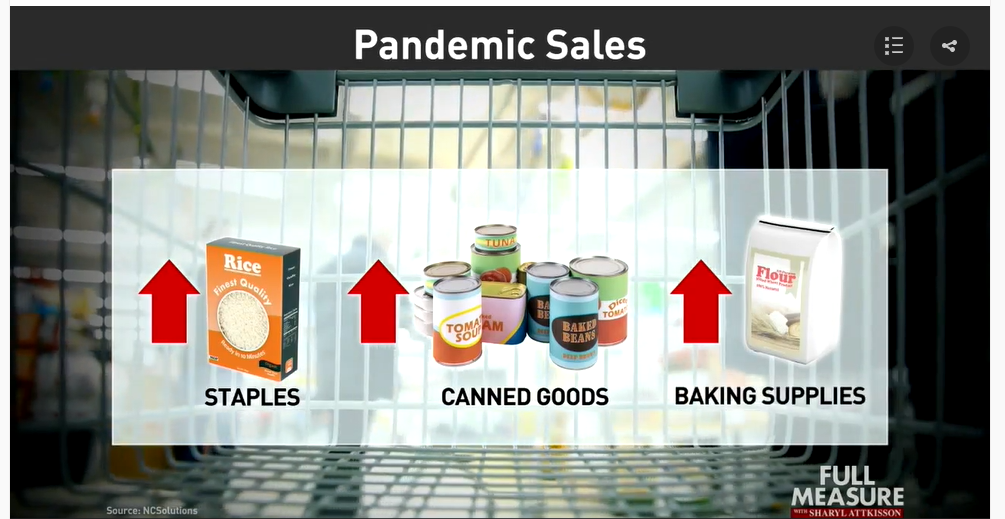

But staple food items also saw big rises, as consumers rushed to fill their pantry’s with staples, canned goods, and baking supplies. Overall, grocery spending up 14% since start of the pandemic.

Lisa: Did you go through a period of frustration and then sort of acceptance of all of this?

Gutleben Becker: In normal life, we got really used to our very specific products and the things that we loved. And that was really great, but we’ve learned to adapt and most of us are not finding the things that we love. And that feels very appropriate for these times.

But how did the retail structure that usually means we never see an empty shelf or missing product break down so quickly?

Brian Gibson: I think it started happening long before we ever started to see store shelves being empty.

Professor Brian Gibson is the Executive Director of the Center for Supply Chain Innovation at Auburn University in Alabama.

Lisa: So we know there’s products that everybody grabbed for immediately, because we we’re just living in this big unknown, but how did that rapid transition from everything to nothing affect the supply chain globally?

Gibson: You start to see raw material suppliers in foreign countries where the pandemic hit earlier, they’re closing down facilities, they’re telling everybody to stay at home. So pretty soon, your raw materials and your components, and all your supplies, are slowing down on their flow into the United States. And that ultimately catches up because a lot of companies have gotten very lean over the last 20 years.

For manufacturers, being ‘lean’ means only storing the parts and components you need right now, relying on 24/7 supply chains to deliver new inventory just at the right time. It saves billions in storage, but it means any glitch in the chain, and things stand still.

Supply chain disruption is nothing new. If you’ve ever lived in a place that’s experienced a natural disaster, like a hurricane, you know what it’s like when everyone runs out to buy the same supplies. The grocery and hardware stores empty fast. What made the pandemic different was that the same thing was happening in every city, in every country around the world. All at the same time. no supply chain, even the best-designed, was going to have enough product to cope with the sudden demand.

Fight government overreach. Support free speech and free press. Donate to Attkisson v. DOJ here.

Lisa: Walk me through the different chapters of that since the pandemic began.

Gibson: So, I think early on in the pandemic it was issues of the PPP, the personal protective gear, the masks, the sanitizer, home products because people didn’t know how long they were going to be at home. So, toilet paper, cleaning products, paper towels. There were reports of meatpacking plants having problems with COVID making people nervous, they see it on the news and, “I got to go out and buy some chicken, I got to go out and buy a steak, got to go out and fill up my freezer.

Producers have responded by trying new tactics to make their limited resources and factory capacity go further.

Gibson: One thing that the companies have done to try and speed up that process is it cut back a little bit on the variety. So instead of making six different varieties of toilet paper in 12 different packaging sizes, let’s focus on two brands in our portfolio, and go with four or five packaging options.

But while consumers may be learning to live with less, the pandemic has meant a boom for online retailers and delivery services like UPS, which delivered 6.3 billion packages last year, an increase of 13.7%.

And FedEx last summer saw a 31% rise in deliveries, leading the company to predict that by 2023, 100 million parcels will be shipped each day in the U.S. — growth that’s three years ahead of what was predicted before the pandemic.

And with the majority of products coming into the country in giant, steel shipping containers like this, the pandemic has also meant a boom for America’s ports. Here in Baltimore, business has been growing for the last 11 months with imports and exports moving through the port increasing 10%.

Lisa: How’s business at the port?

William Doyle: Business has been really good.

William Doyle is the executive director of the port of Baltimore.

Lisa: How much has e-commerce spiked your business here at the port?

Doyle: Tremendously. Since July, we’ve had at least 18 unscheduled rotation container ships come through the port. And that’s the equivalent of approximately 30,000 containers that we wouldn’t have ordinarily had.

At some other ports, there are so many ships coming in, it has taken days or weeks to unload them. and now, a new shortage that’s impacting global trade: not enough empty containers.

Doyle: There is a shortage of containers overseas. So, we do move empty containers through the Port of Baltimore on the ships back to the loading ports in Asia and Indian sub-continent.

Experts say the massive increase in e-commerce as a result of lockdowns is likely permanent, but what about other changes?

Lisa: What happens now?

Gibson: I’ve read a lot, put it this way, of pundit saying, “Oh, we’re going to fundamentally change how we operate supply chains. We’re going to bring everything back to the United States, everything near shore. We’re going to do this and this and this.” And we’ve talked to companies, and they said, “No, we’re not going to do a wholesale change of our supply chain, but we’re going to be smarter, and we’re going to start off with coming up with better contingency plan.

For Christine and countless other parents, the pandemic has changed buying habits with little expectation things will ever be the same.

Gutleben Becker: I think most moms are shifting to online and I think we’re so busy and focused on our kids and schooling that we don’t notice that things don’t arrive when we order them. So as long as we have some kind of milk and some kind of fresh produce, we just keep moving forward.

And just as we’re learning to live with change and disruption at the grocery store, the supply chains that link modern commerce are also learning and adapting, making them stronger in the future.

Sharyl (on-camera): Is there any hope for a solution to the shortages?

Lisa (on-camera): In the short term there are still going to be things you can’t find, like masks and first aid items because of high demand. In the longer term, President Biden has ordered reviews of global supply chains for everything from computer chips to food. The White House wants to encourage more domestic production for key products but hasn’t said how they’ll do it.

Click on the link below to watch the story on FullMeasure.news:

http://fullmeasure.news/news/cover-story/empty-shelves-05-07-2021